3d Signals

Smart Factory Assessment

We install within close cooperation with the 3 d signals team the 3d signal-owned IT infrastructure. Within a few hours, you will be able to visualize the levers and optimization potentials of your plant machinery, cells, and stations.

Immediately after installation, you are able to view on your mobile or any other display of your IT.

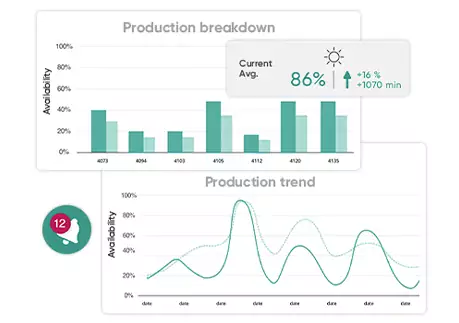

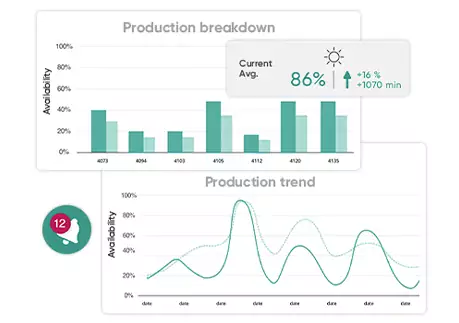

By a dashboard application, the Smart Factory appliance is able to show the sunk holes, bottlenecks, and anomalies to get first information over your production performance in a quick check scenario.

Value Ad for Production with 3d signals teamwork

We offer the modular and purposeful configuration and setup for your yet installed and also for a new 3 d signals installation to gain optimal results for the derivation of performance matters and the possible need for action.

Our experts configure the system on-site and create a dashboard that delivers an optimized overview of machinery data and performance.

NAXconsulting creates ideal processes and flows within the model phase and derives an implementation plan for operational levers to improve the overall performance.

Jointly with the 3 d signals team, we will train your teams for the use of the most important reports and activities. Within the implementation phase with your teams, the results of the model phase will be transposed to your machinery and layout settings to guarantee an ideal efficiency and effectivity improvement in terms of sustainable further development of your operational processes.

Description of the 3 d signals Smart Factory Platform

3 d signals offers an application to record and visualize your production performance in real-time. The data can be transferred to your control station software systems to secure an ideal and sustainable lever of potentials. With our partner 3 d signals, you get a new level of insight into your manufacturing processes by using this IoT solution as a new cornerstone of your digital transformation efforts.

Portfolio of Reportings to visualise the KPIs and Leffers of improvement

Naxconsulting is offering the opportunity to connect all machines, productions-cells, and other parts of production with the 3d signals IoT solution. The continuous real-time implementation of data into your production data hub will create an added value in the optimization of precise preproduction planning.

Especially older machine formats and machines in high distanced productions plants can be connected easily! A true quick win that visualized in immediate improvement of productivity.

The multi and real-time reports of production in combination with the experienced NAXconsulting experts are realizing safe, true holistic results. The training of your teams and the continuous activities for improvement will secure the best possible results and quality.